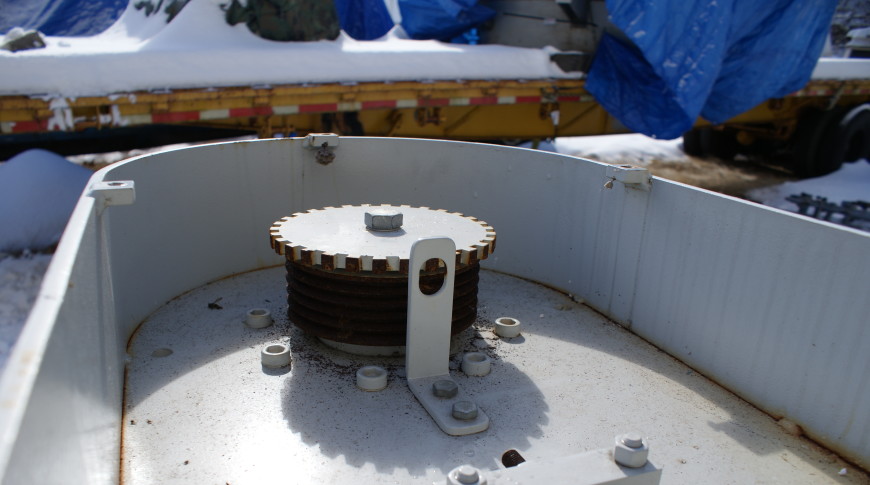

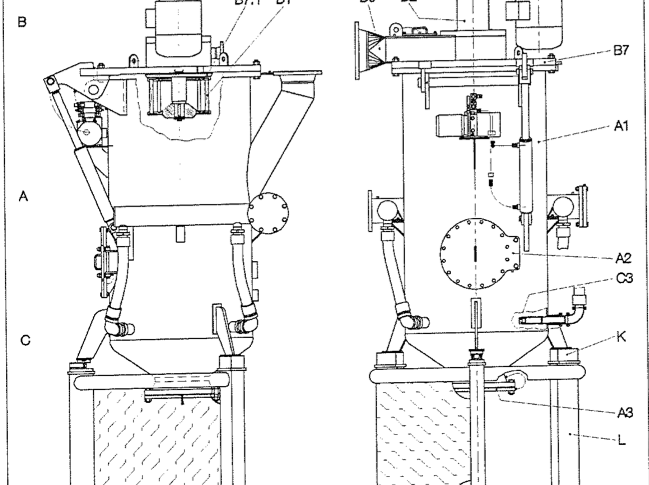

Purchased custom new by ADM (Archer Daniels Midland) for cocoa food processing at a cost of over $450,000 , it was never installed or used. It was recovered (unfortunately the same can’t be said for the scrapping of two $250,000 steam reactors), transported, marketed, inspected and refurbished by manufacturer and sold to a carbon-black pyrolysis startup company.

It is the second largest production size, 4x larger than the next series. The largest 1500 series has never actually been used due to uneconomical power requirements.

Alpine Jet mills are the most efficient and cost-effective method to achieve particle size reduction, across a spectrum of materials, hardness, to literally nuclear grade, micron size for pharmaceutical or industrial processes.